Top search keywords: Gb38031 GB31241 Environmental equipment Production line equipment

Top search keywords: Gb38031 GB31241 Environmental equipment Production line equipment

1. Equipment picture:

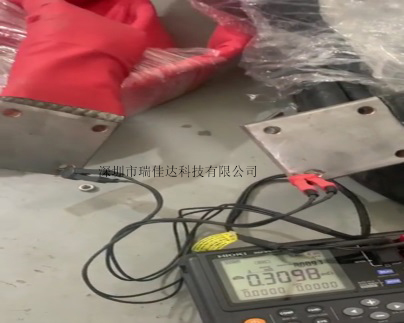

2. Standards for short circuit test: for example, GB / T 31485-2015

3. Short circuit machine control cabinet:

Innovative design of large circuit switch for short circuit equipment. In order to simulate and test the large current generated at the moment of battery short circuit, contact switch is needed to control. At the moment of short circuit test, a large current will be generated. At present, the conventional switching device in the market is placed in a vacuum box for contact. The high current suction device needs to be vacuumized in the early stage (for example, it needs to confirm whether there is oil in the vacuum pump before the experiment, and it needs regular refueling and maintenance), and the suction device must be precision processed and assembled to a high standard. To meet the requirements.

Our company selects high current switch, all electric control. No need for vacuum box, with national quality certification. Short circuit machine control cabinet is not only small in size, easy to use, long life, fast response. Solved the industry difficulty "control cabinet + 4m copper ribbon resistance < 1m Ω"

4. Resistance box:

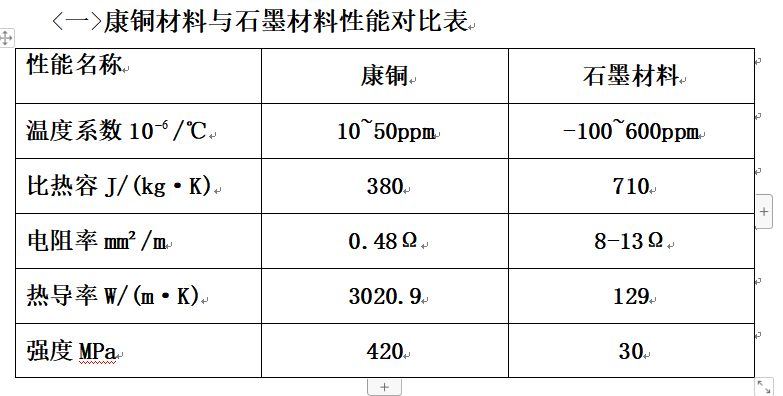

The short-circuit test needs different resistance value tests, the convenience of resistance value switching of resistance box and the high stability and safety of resistance materials are particularly important. According to different test standards, different resistance values need to be achieved by mechanical switch switching. At present, graphite, stainless steel and constantan are mainly used in the resistance material market. The performance and stability of these three materials are not the same. Constantan has stable material performance and low temperature drift coefficient, which can ensure that the resistance does not change with the change of current in the short circuit experiment. Solve the industry pain point of "large current resistance change rate at the moment of short circuit"

The temperature coefficient of the material determines the change of the resistance value of the material due to the temperature change. The higher the specific heat capacity of the material, the slower the speed of heat absorption or heat dissipation of the material. The resistivity of a material is an attribute reflecting the blocking effect of material on current, which reflects the conductive ability of the material. The thermal conductivity of a material is a physical quantity indicating the thermal conductivity of the material, and the strength of the material determines the safety of the product. The correct choice of material scheme is not only the premise for the expected realization of technical performance of the product in the process of putting into use, but also the guarantee for the safety performance of the equipment. The key of this product design is how to meet the strong thermal stress and current stress generated in the process of instantaneous large current test, and the long-term stability of various electrical properties under this stress condition.