Top search keywords: Gb38031 GB31241 Environmental equipment Production line equipment

Top search keywords: Gb38031 GB31241 Environmental equipment Production line equipment

With the vigorous development of new energy vehicles, battery safety problems occur frequently, and the battery safety problems are also highly valued by relevant enterprises in the industry, national security and testing departments. The relevant testing standards and requirements at home and abroad are also higher and higher, and more attention is paid to the professionalism of testing methods and the authenticity and traceability of testing results.

Careful customers will notice that in the past few years, the battery extrusion test will always happen. At the moment when the extrusion head contacts the battery, the pressure tends to overshoot greatly, and the overshoot is far beyond the promised accuracy index. At this time, extrusion testing machine manufacturers will explain that this is the principle of inertia, need to slow down in advance to ensure the pressure accuracy. Unidentified laboratory testers can only listen to it.

In fact, this explanation does not hold water at all. Can you imagine that in the real world, a car will decelerate ahead of time and then crash gently? The reason for this kind of sound is that the extrusion testing machine manufacturer's own level is not enough, and the response frequency of the control system is too low, which leads to the poor dynamic performance of the control system.

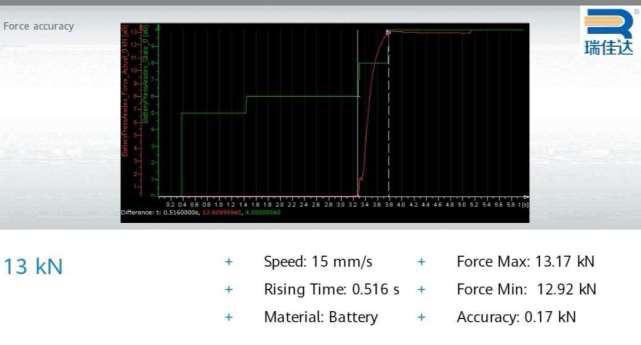

After painstaking investigation, ruijiada found the common pain points in this industry. We, together with Wanxun automation and German aradex company, adopted the microsecond level response control system (see Figure 1 below), and created a test record of "no overshoot" in the field of extrusion test. According to the actual verification of leading enterprises in the battery industry, the pressure accuracy of rjd4t extruder is controlled within ± 0.2kn under the extrusion pressure of 15mm / s and 13kn (see Figure 2 below), and this test accuracy is far better than that of UN38.3 standard under the extrusion pressure of 15mm / s and 13kn force.

(核心部件图一)

(实测的数据曲线,图二)

You should not underestimate this 0.516 second. Between the lightning and flint, the control system detects that the pressure rises from zero, so it quickly adjusts the output to make the pressure reach 13kn smoothly. Those who are familiar with automatic control must remember to control the three indexes of "stability, accuracy and speed". These three performances are often controlled by each other, while ruijiada's extruder has achieved the perfect balance of the three performances.

This set of professional servo motion controller has been successfully developed since October 2018, and has been applied to all kinds of 20-1000kn needle punched extrusion testing machines since it was put on the market. It meets the requirements of all battery testing standards at home and abroad, and also fundamentally solves the problem that in order to ensure the pressure accuracy, it needs to slow down in advance when approaching the tested battery.

Shenzhen ruijiada Technology Co., Ltd. shall bear the false legal liability for the above technical content. Friends or customers in the industry are welcome to exchange.

Shenzhen ruijiada Technology Co., Ltd

R & D Center

June 2019